With an eye on the environment, Weller leads in the remanufacturing of heavy duty driveline components. We take transmissions, automated and manual, differentials, driveshafts, steering gears, and more and remanufacture them by utilizing high quality parts and processes to reduce the amount of waste. Our remanufacturing process is a fully engineered solution for efficient and cost-effective repair, removing otherwise defunkt units and parts from the path to a landfill. We provide a service alternative to the OEM that matches their original quality standards. This ensures uniformity in performance and product life.

The Original Recycler

MEMA: Motor and Equipment Remanufacturing Association

MEMA’s Center for Sustainability champions remanufacturing and other environmentally responsible practices that deliver economic and performance benefits. With deep roots in the transportation industry, MEMA represents the broader sustainable manufacturing community across multiple sectors. Their network includes manufacturers, suppliers, academic institutions, and professional service firms working together to advance the value of sustainable manufacturing.

What is Sustainable Manufacturing?

Simply put, sustainable manufacturing means manufacturing with reuse. It is a process that restores original products in a controlled factory setting, producing goods that are like new, often better than the originals. These products deliver like-new quality, superior value, and a positive environmental impact. By conserving materials and embodied energy, sustainable manufacturing reduces landfill waste and supports a circular economy.

Business Practices

The Weller Way Standard is a set of codes and practices that are followed across our company. We value people, integrity, respect, and a sustainable future.

Our Remanufacturing process is more than just replacing worn out parts. Our experienced remanufacturers disassemble old units to determine what causes failures to improve on our meticulously designed remanufacturing process, and to salvage perfectly good parts that would have been destined for the trash. Units with parts that would otherwise be thrown away can be given a second life and combined to reduce waste and produce new units. In fact, even though we salvage original OEM parts, those parts still must be tested to ensure that their performance meets or exceeds their OEM counterparts

We are committed to manufacturing superior quality products that help our customers build their businesses. We share the same values as our customers, and promise to do business with integrity and respect for the environment.

What is Remanufacturing?

Repairing a unit is a great option when it's cost effective and it works. In many cases, repair can be the best route to take. However, sometimes you have to go with a rebuilt or remanufactured unit to ensure that it performs as it should for years to come. The truth is that there are a lot of options out there and it can get confusing. To help you make an informed decision, here's how all three options compare:

Repair: fixes only damaged components.

Rebuilt: reconditioned units that are cleaned, inspected, and only worn or broken parts are replaced to like-new condition.

Remanufactured: a rebuilt unit done by a team of specialists in a remanufacturing facility and done to OEM specifications.

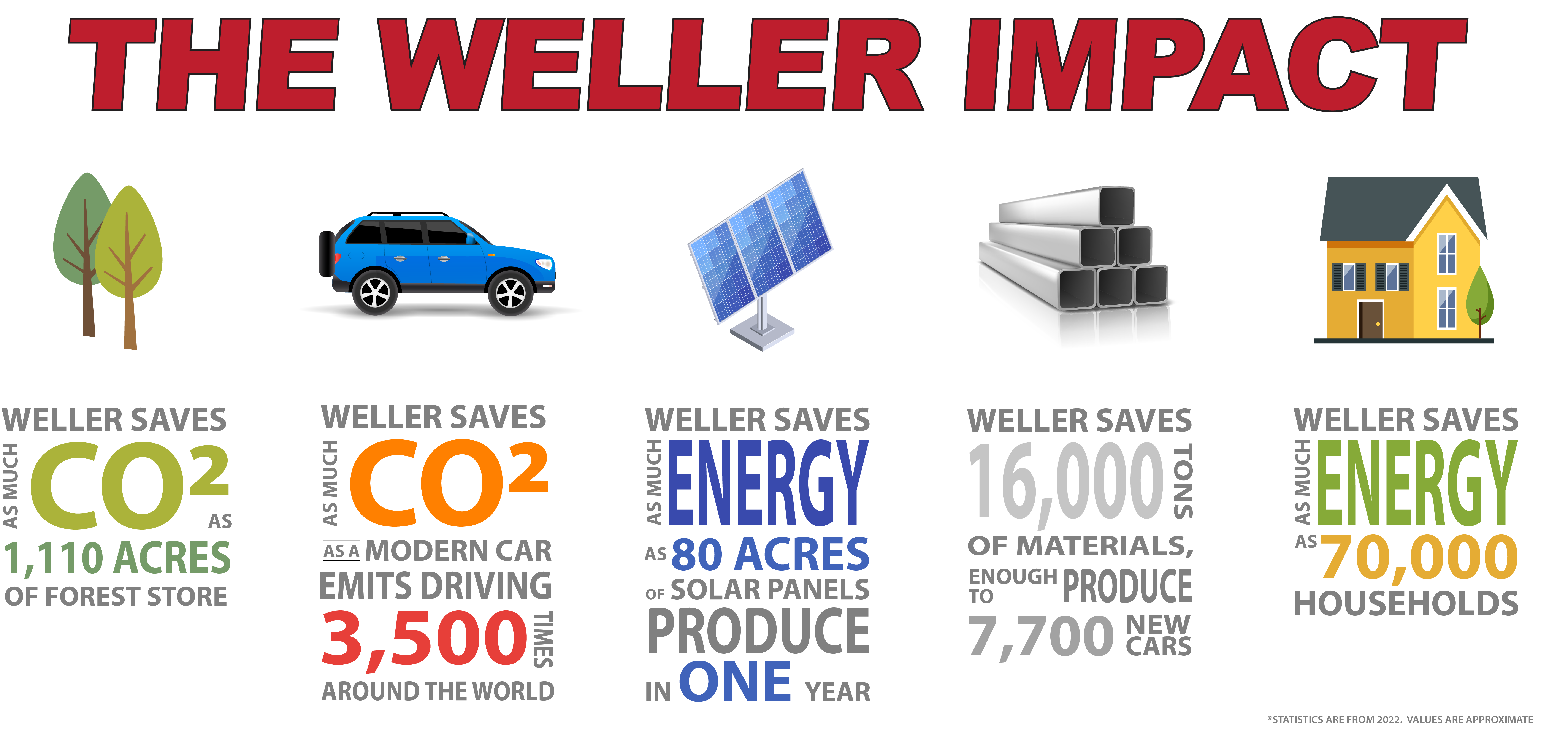

How We Practice Sustainability

Being a remanufacturer, Weller understands the significance of recycling and the impact of waste on the environment, which is why we take the initiative every day to play our part in reducing waste. These are just a few of the stops on our journey to sustainability.

- Recycling

- Aerosol Cans

- Steel

- Pallets

- Paper

- Building Energy Efficiency

- LED lighting at most locations and motion sensor LED lighting in our warehouses

- Heat recovery from air compressors and hot tanks in cooler months

- Smart chargers to reduce power consumption

- Switching to electric forklifts to reduce emissions

- Delivery Fuel Efficiency

- Implementation of software to increase routing efficiency and reduce fuel consumption

- Primarily use LTL to consolidate shipping to reduce fuel consumption